|

|

Analysis of Films of Display & Touch Panel - A Few Examples (Ref: Ellipso Technology) |

|

| |

|

|

|

|

|

| |

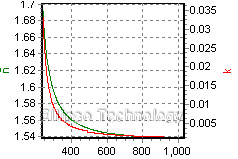

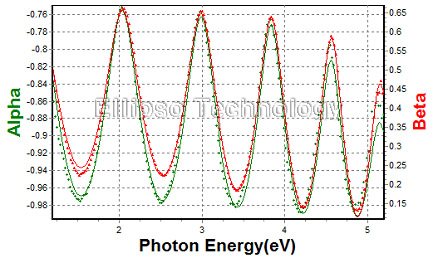

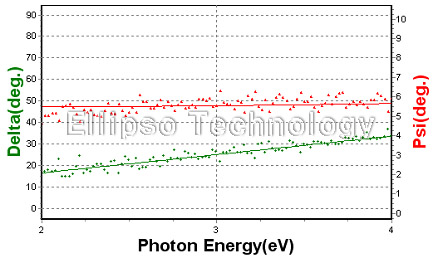

1-1. SiO2/HardCoating/Primer on PET |

| |

|

|

| |

Thickness of Film (From Top) :

SiO2 = 18.29 nm

Hard Coating (93.2 %) = 3258.8 nm

Primer = 63.33 nm |

| Substrate = PET |

|

|

|

|

| |

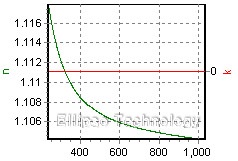

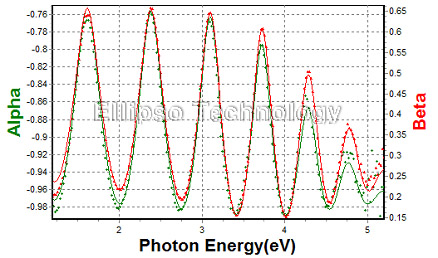

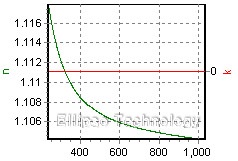

1-2. SiO2 on Cu |

|

| |

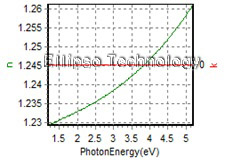

| Thickness, SiO2: 343.466 nm |

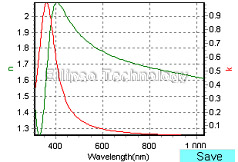

| R.I. Dispersion of SiO2 |

| Substrate : Cu |

|

|

| |

1-3. SiO2/GI on Cu |

|

| |

Thickness, SiO2: 343.466 nm

GI : 38.527nm |

| R.I. Dispersion of SiO2 |

| Substrate : Cu |

|

|

|

2. Silica Nano Particle |

[TOP] |

|

|

| |

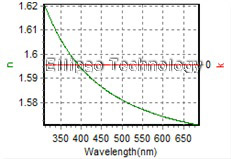

2-1. Silica Nano Particle on PET |

| |

|

|

| |

| R.I. Dispersion of SiO2(53.1%) Main Layer |

| Substrate = PET |

Layers (From Top) :

SiO2(33.7%)+void(66.3%) = 38.1 nm

SiO2(53.1%)+void(46.9%) = 52.7 nm

SiO2(101.8%)+void(-1.8%) = 35.4 nm |

|

|

|

| |

Silica Nano Particle on top of a uniform 30-nm-thick SiO2, is expressed as a composite two-layer structure, each consisted of SiO2 and void. |

|

| |

2-2. Silica Nano Particle on Hard Coated PET |

|

| |

|

|

| |

| R.I. Dispersion of SiO2(52.4%) Main Layer |

| Substrate = PET |

Layers (From Top) :

SiO2(26.8%)+void(73.2%) = 34.4 nm

SiO2(52.4%)+void(47.6%) = 67.8 nm

SiO2(101%) = 36.7 nm

HC = 7993.6 nm

Primer = 86 nm |

|

|

|

| |

Silica Nano Particle on top of a uniform 30-nm-thick SiO2, is expressed as a composite two-layer structure, each consisted of SiO2 and void. The thickness of Hard Coating and that of primer are also determined. |

|

|

|

|

| |

3-1. AgOx on c-Si |

|

| |

| Thickness, AgOx: 23.347 nm |

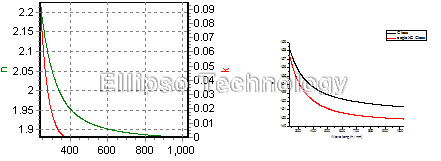

| R.I. Dispersion of AgOx |

| Substrate : Crystalline Silicon |

|

|

| |

3-2. AgOx on c-Si |

|

| |

| Thickness, AgOx: 19.789 nm |

| R.I. Dispersion of AgOx |

| Substrate : Crystalline Silicon |

|

|

| |

3-3. AgOx on c-Si |

|

| |

| Thickness, AgOx: 19.739 nm |

| R.I. Dispersion of AgOx |

| Substrate : Crystalline Silicon |

|

|

|

|

|

| |

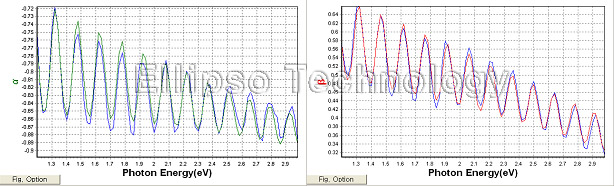

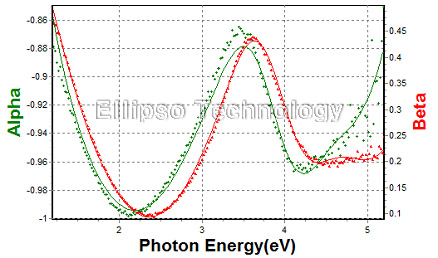

4-1. PR on Al2O3 |

|

| |

|

|

| |

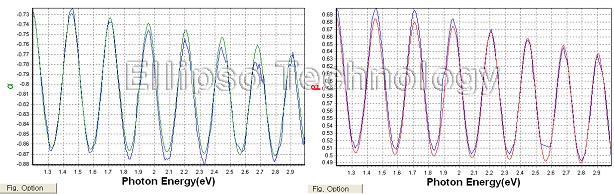

| PR Thickness : 1784.29 nm |

| Substrate : Al2O3 |

| R.I Dispersion of PR |

|

|

|

|

| |

4-2. PR/Gan on Al2O3 |

|

| |

|

|

| |

Thickness of Film (From Top) :

PR = 2482.69 nm

GaN (91.4 %) + PR (8.6 %) = 6198.79 nm

GaN (77.8 %) + void (22.2 %) = 69.09 nm |

| Substrate : Al2O3 |

|

|

|

|

| |

4-3. PR on c-Si |

|

| |

| Thickness, PR : 1423.475 nm |

| R.I. Dispersion of PR |

| Substrate : Crystalline Silicon |

|

|

|

|

|

| |

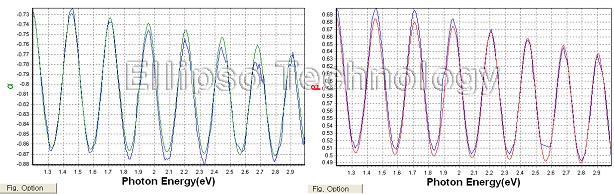

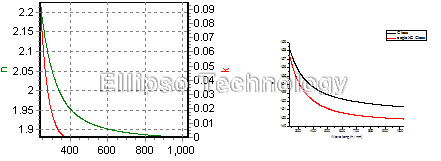

5-1. SiNx on Glass |

|

| |

|

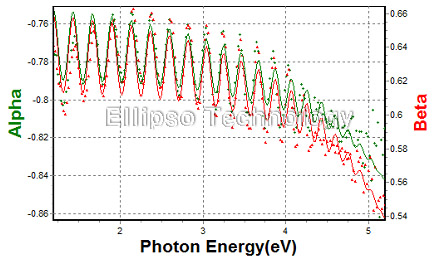

| SiNx Thickness : 372.74 nm |

| R.I. (@633 nm) : 1.8823 |

| Substrate : Glass |

|

|

|

| |

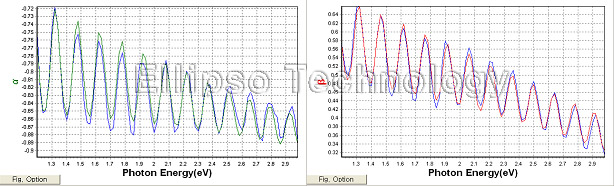

5-1. SiNx on Glass |

|

| |

|

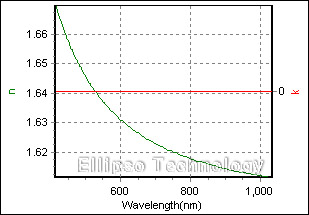

| Thickness SiNx : 468.294 nm |

| R.I. Dispersion of SiNx |

| Substrate : EagleXG Glass |

|

|

| |

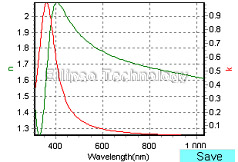

|

| |

The complex refractive index dispersion of SiNx(left) and the refractive index dispersion of EgleXG-Glass(right, red line). The refractive index of soda-lime glass(right, black line) is compared with that of EgleXG Glass. |

|

|

|

|

| |

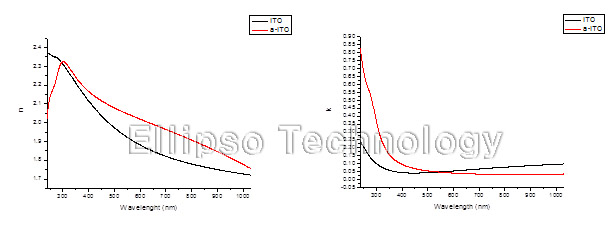

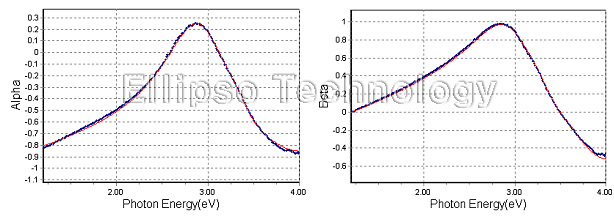

6-1. ITO on glass |

|

| |

|

|

| |

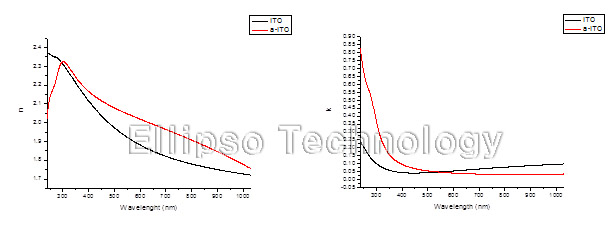

6-2. a-ITO on Glass |

|

| |

|

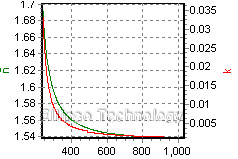

| Thickness a-ITO : 76.85 nm |

| R.I. Dispersion of a-ITO |

| Substrate : EagleXG Glass |

|

|

|

| |

|

| |

| R.I. Dispersion of ITO & a-ITO |

|

| |

|

|

| |

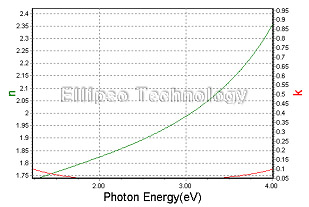

6-3. ITO on Glass |

|

| |

|

|

| |

| ITO Thickness 63.26 nm |

| R.I. Dispersion of ITO |

| Substrate: Crystalline Silicon |

|

|

|

|

| |

6-4. ITO on Sapphire |

|

| |

|

| ITO Thickness : 160.66 nm |

| R.I. Dispersion of ITO |

| Substrate : Al2O3 |

|

|

|

| |

|

|

| |

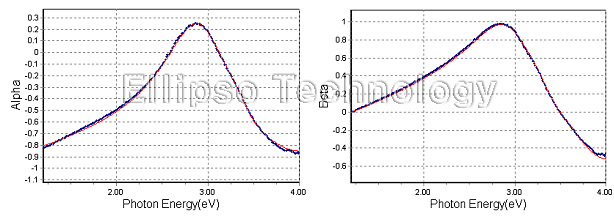

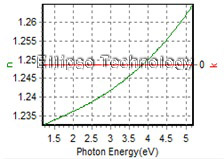

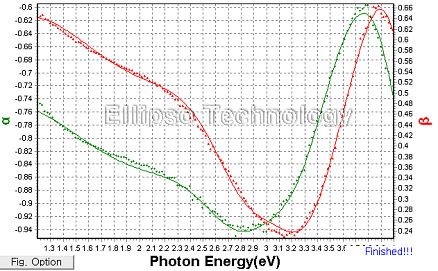

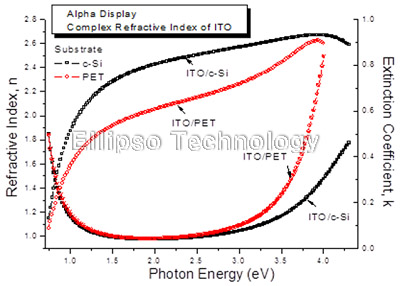

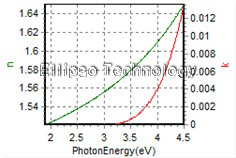

6-5. ITO on c-Si, ITO on PET : The Complex Refractive Index Dispersion |

|

| |

|

From the complex refractive index of ITO, one can recognize that density and/or light absorption of ITO film depends on the substrate upon which it is coated.

ITO film coated on c-Si wafer is denser than that on PET substrate. Further, ITO film coated on c-Si wafer is less light-absorbing than that coated on PET.

Thus ITO film on c-Si wafer is superior to that on PET. |

|

|

|

|

|

|

| |

7-1. Acrylic Resin on Glass |

|

| |

|

Thickness Acrylic resin :

2128.73 nm |

| R.I. Dispersion of Acrylic Resin |

| Substrate : EagleXG Glass |

|

|

|

| |

|

|

|

|

|

| |

8-1. AF Coating on Glass |

|

| |

|

| AF Coating(24.7 %) + void(75.3 %) = 14.78 nm |

| R.I. Dispersion of AF Coating |

| Substrate : Glass |

|

|

|

| |

|

|

|

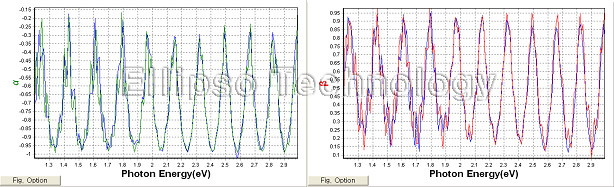

9. PAC(Photo Active Compound) |

[TOP] |

|

|

| |

9-1. PAC(Photo Active Compound) on Normal TFT |

|

| |

|

|

| |

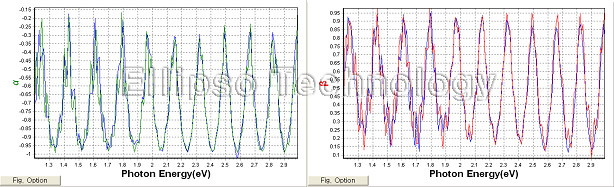

| R.I. Dispersion of PAC |

| Substrate = Glass |

Layers (From Top) :

PAC(87.576+void(21.4%) = 25.146 nm

SiN(56.7%)+void(43.3%) = 1970.908 nm

SiN(50.9%)+void(49.1%) = 269.249 nm

TFT(35.5%)+void(64.5%) = 180.532 nm

TFT(52.2%)+void(47.8%) = 54.827 nm

TFT(66.7%)+void(33.3%) = 86.526 nm |

|

|

|

|

| |

9-2. PAC(Photo Active Compound) on Retina TFT |

|

| |

|

|

| |

| R.I. Dispersion of PAC |

| Substrate = Glass |

Layers (From Top) :

PAC(100%) = 2177.246 nm

PAC(86.4%)+void(13.6%) = 48.9 nm

TFT(42.7%)+void(57.3%) = 47.313 nm

TFT(67.6%)+void(52.4%) = 54.652 nm

TFT(44.5%)+void(55.5%) = 62.867 nm |

|

|

|

|

|

|

|

| |

10-1. Au on Glass |

|

| |

| Thickness, Au : 40.182 nm |

| R.I. Dispersion of Au |

| Substrate : Glass |

|

|

|

|

|

| |

11-1. PS/Au on Glass |

|

| |

Thickness, PS : 15.797 nm

Au : 51.639 nm |

| R.I. Dispersion of PS |

| Substrate : Glass |

|

|

|

|

|

| |

12-1. TIPS-PEN/Au on Glass |

|

| |

| Thickness, TIPS-PEN : 150.944 nm |

| R.I. Dispersion of TIPS-PEN |

| Substrate : Glass |

|

|

| |

12-2. TIPS-PEN/Au on c-Si |

|

| |

| Thickness, TIPS-PEN : 144.407 nm |

| R.I. Dispersion of TIPS-PEN |

| Substrate : c-Si |

|

|

|

|

|

| |

13-1. Polymer on Glass |

|

| |

| Thickness, Polymer : 97.582 nm |

| R.I. Dispersion of Polymer |

| Substrate : Glass |

|

|

|

|

|

| |

14-1. TiOC on c-Si |

|

| |

| Thickness, TiOC : 106.653 nm |

| R.I. Dispersion of TiOC |

| Substrate : c-Si |

|

|

|

|

|

| |

15-1. CuNx on c-Si |

|

| |

| Thickness, CuNx : 28.058 nm |

| R.I. Dispersion of CuNx |

| Substrate : c-Si |

|

|

| |

15-2. CuNx on c-Si |

|

| |

| Thickness, CuNx : 82.097 nm |

| R.I. Dispersion of CuNx |

| Substrate : c-Si |

|

|

| |